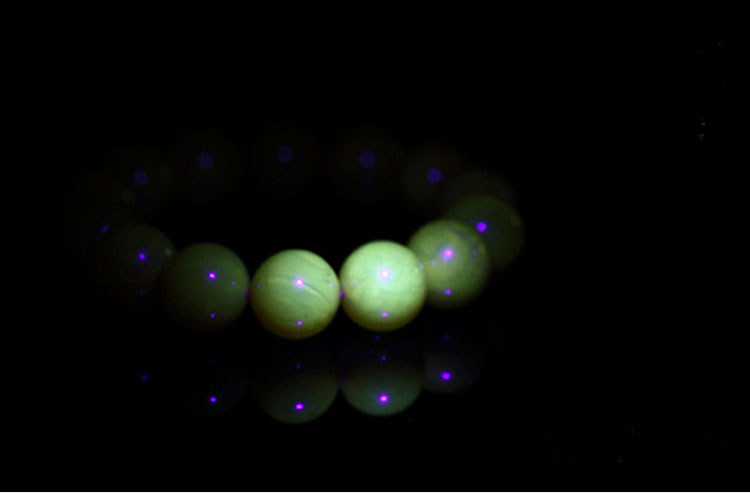

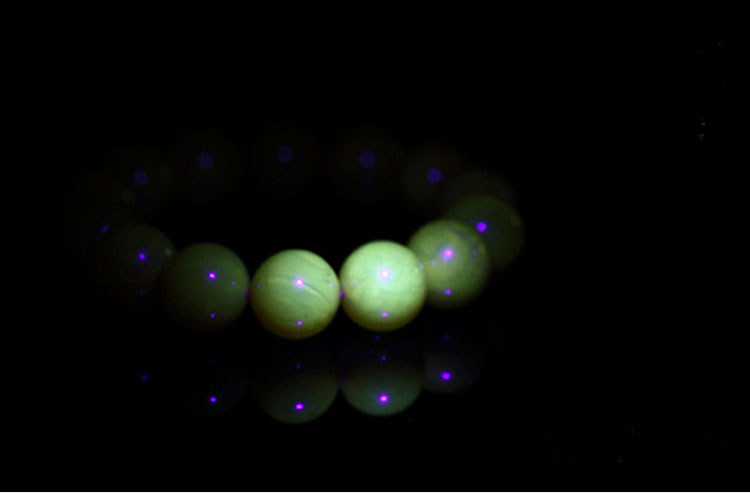

Fluorescent wax glub

Artificial fluorescent amber wax special glue, high hardness and high simulation

1. Amber beeswax is a blue fluorescent high-simulation amber beeswax glue modified by special resin.

2, the main features: colorless and transparent, low viscosity, crystal clear after curing, high hardness, can be blue fluorescent or green fluorescent, can be polished,

3, the surface is smooth, shiny, anti-aging, waterproof, oil-proof, dust-proof.

4, can add a variety of colors, products through the EU ROHS environmental certification.

5, Jiaozhidao specializing in the production of a variety of artificial amber honey wax, can be customized according to requirements.

Amber wax adhesive range:

Professional application in a variety of simulation amber, blood, beeswax and handicrafts perfusion molding (more applications, please contact us)

Product Parameters:

Product Series:

Product Parameters:

| Model: | 8101A | 8101B |

| Color: | Transparent viscous body | Transparent liquid |

| Viscosity: | 1500-2500cps | 200-300cps |

| Specific: | 1.0g/cm3 | 0.9g/cm3 |

| Shelf life: | 6 months | 6 months |

| Ratio: | A: B = 2: 1 (weight ratio) | |

| Use time: | 25 ° C × 40g ×10minutes | |

| Gel time: | 25° C × 40g × 30minutes | |

| Hardeness: | SHORE D≥83 | |

Product Series:

Our company specializes in producing all kinds of simulated amber beeswax rubber. We can customize the product characteristics according to customer requirements. Welcome to contact us online or call us. We will have professional consultants and technical engineers to answer and customize the products that suit your needs.

Product Certification:

EU ROHS Environmental Certification MSDS Export Safety Data Sheet

| Model | Color | Weight Ratio | Mixed Viscosity | Curing Time | Hardness | Product Characteristics |

| 8100AB | Transparent | 2:1 | 400-500 | 25°C X 40G X 30minutes | ≥83D | High hardness, high gloss, low density |

| 8101AB | Transparent | 2:1 | 400-500 | 25°C X 20G X 30minutes | ≥83D | High hardness, high gloss, blue fluorescence |

Product Certification:

EU ROHS Environmental Certification MSDS Export Safety Data Sheet

Gluing Method:

1. Prepare the electronic scale and the glue tool.

2. Pour A and B into the plastic container according to the proportion and stir evenly and defoam under vacuum.

3. Pour the glue into the mold for heating and curing.

Precautions:

1. Please clearly check the label on the package before matching the glue, and confirm the ratio of the ratio of the A agent to the B agent.

2, the glue tool should be clean and dry, no dust, water and oil

3. Mix the A and B components according to the proportion and stir evenly to avoid unevenness or lack of hardness.

4. Since the glue starts to react and heat, the more the amount of glue is, the more heat is generated, and the curing time is also shortened. The shorter the time that can be used, so please apply the proper amount of glue according to the time of filling. So as not to cause waste.

5. After the glue is finished, seal the AB agent package to prevent debris or moisture absorption, and ensure the normal use of the next time.

6, a very small number of people exposed to the glue for a long time will produce mild skin allergies, it is recommended to wear protective gloves when used, stick to the skin can be wiped off with acetone, Tianna water or alcohol, and cleaned with detergent

7, before mass use, please try a small amount, master the use of the product skills, so as not to make mistakes

Package Storage:

1. Packed for each group of 30KG, A glue 25KG / pot, B glue 5KG / pot

2. After the plastic bucket is opened and the glue is poured out, it needs to be covered immediately to avoid contact with the air for a long time, which causes the glue to oxidize and crystallize.

3, the glue must be sealed and stored in a cool and ventilated place to avoid high temperature or sun exposure

4. The glue may crystallize in the low temperature condition in winter, and it needs to be dissolved in a 60 degree oven before use.

5. The shelf life of this glue is 6 months. If the shelf life is exceeded, please try it in small amount. If it is qualified, you can continue to use it.

PREVIOUS:no article

NEXT:High hardness and high simulation, artificial amber beeswax resin ab glue